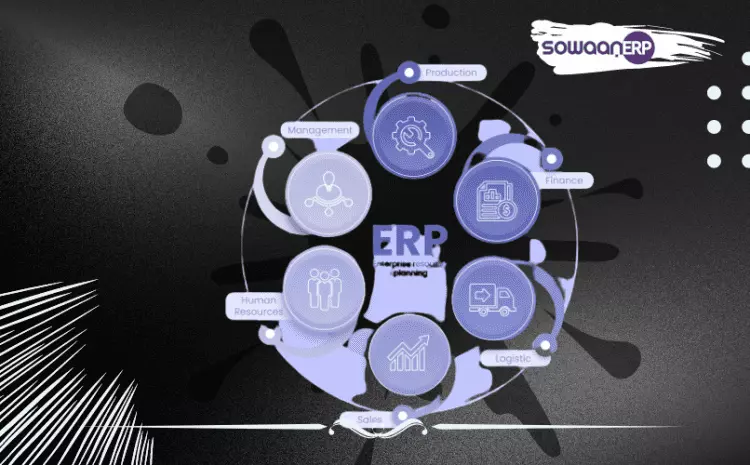

Supply chain management ascribes organizations reacting to market changes depending on ERP solutions. ERPs provide a comprehensive outlook of all corporate activities, boosting the entire supply chain management field. ERPS also assist manufacturers where and how to organize their own inventory and work-in-progress jobs, making it easier for them to answer to customer orders more confidently.

In this article, you will learn the ropes about how ERP solution manufacturing in Pakistan integrates supply chain management for upgrading overall business operations.

Better Fusion SCM structure using ERP Integration

Let’s talk about how ERP is great for manufacturing, SCM has always provided precise problems for manufacturers, especially those that make specialized products. Today, ERP is all jacked up, it’s uncommon for a manufacturer to engage with just a small number of carefully chosen suppliers; instead, most custom manufacturers scour a vast network of vendors to discover the best service provider who can provide high-quality features and materials at the best price and on time. Hence, the best ERP for manufacturing helps companies improve their SCM procedure in many ways, such as:

- Integration of internal business processes;

- Improvement of information flow between different departments within the company;

- Better inventory management;

- Improvement of the company’s relationships and teamwork with outsourcing suppliers, customers, and partners in the supply chain;

- Improving the efficiency of purchasing processes;

- Increasing a manufacturer’s capacity to assess vendors;

- Properly manage complex supply chain relationships.

Supply chain management upgrading can lead to control of expenses and reduce costs, which ultimately increases profits. It will also make manufacturers more productive and help them finish jobs on time.

Comprehensive ERP Interface

ERPs act as a “one-stop shop” and give manufacturers a unified view of their full supply chain. This lets manufacturers decide what to buy and how to buy it. Managers and executives have a better view of every part of the supply chain, making it easier for them to spot issues or challenges in their supply chain and work more quickly to solve them.

Inventory Management

ERP inventory management systems also simplify the task of tracking the consumption of raw materials, the allocation of on-hand resources to specific jobs, and the tag of low-rate stock items. Hence, improving the productivity of the supply chain.

Vendor Performance

To help companies via implementing the best ERP software in Pakistan to enable better business decisions and boost performance in the present market, ERP systems simplify measuring various providers’ quantitative and qualitative elements. By comparing vendors in terms of quality, cost, and decided delivery times, ERPs make selecting the best one for each task simple.

Procurement Management

ERPs are incredibly useful in the custom manufacturing industry because they streamline the processes of acquiring and supplying the materials and components that are used in production.

Real-Time Reporting

The time and effort vital to assemble data for manual reports increase the chance that fewer reports will be generated, increasing the chance that management will make options based on out-of-date or incorrect information.

Materials Need Analysis

Management of the manufacturing process is essential to the success of every manufacturing organization, and this is where materials requirement planning (MRP) comes in. MRP contains the planning, scheduling, and inventory management systems that ensure production runs smoothly.

For example, ERP solution manufacturing in Pakistan provides manufacturing companies with reliable information, boosting productivity and decreasing overhead expenses. By consolidating all of a company’s operational details, including supply chain management, on a single platform, ERPs help manufacturers streamline their workflows and improve efficiency across the board.

Final Thoughts:

Smart ERP SCM helps manufacturers stay on top of their companies by comprising several conventional ERP capabilities, such as accounting, stock management, and a vendor management system. In addition, it has the technical features and benefits that custom manufacturers require to meet their particular manufacturing issues and optimize their supply chain operations.